01 Core warehousing

Engines that have completed their respective jobs

will be stocked to be reborn as rebuilt engines.

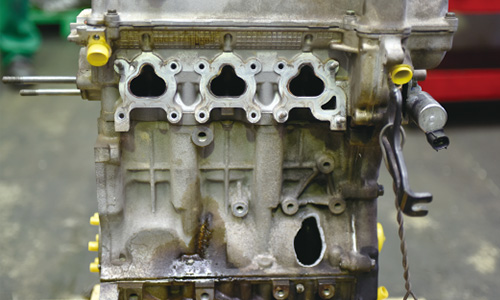

02 Disassembly

The engine core, which is the core of regeneration, is all manually

disassembled into pieces.

After determining the quality of each part,

it will be released to the next process.

03 Cleaning

The unique cleaning method

that we have cultivated so far is used to thoroughly

remove dirt (sludge, etc.) to the inside

of the engine according to each mother’s body.

We perform more careful

cleaning by mechanical

cleaning and manual manual work.

04 Check

In addition to manual work using a micro gauge,

high-precision laser sensors are used for measurement

to improve work efficiency and stabilize quality.

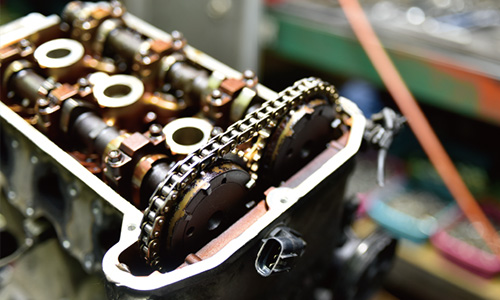

05 Processing / Adjustment

Each measured and checked part is processed

by a surface grinding machine,

high-precision cylinder honing machine, etc.,

and then made its own adjustments and measured

again before proceeding to the next process.

Making full use of the high-precision honing machine

used by domestic automobile manufacturers,

the inside of the engine cylinder is finished

precisely and delicately.

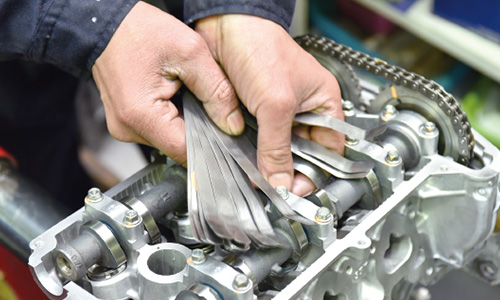

06 Assembly

Using each part that has cleared all the checks,

we will manually assemble each one according

to the manufacturer’s manual,

packed with our unique know-how.

We pay particular attention to the parts

that may cause oil leaks and practice careful work.

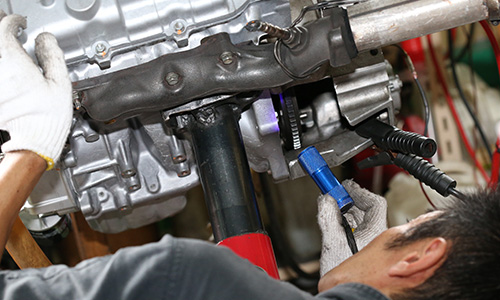

07 Test / Inspection

Using each part that has cleared all the checks,

we will manually assemble each one according

to the manufacturer’s manual,

packed with our unique know-how.

Knowledgeable inspectors always check

with strict eyes and ears,

such as the presence and type of oil leaks and sounds.

08 Shipment

After performing a pre-shipment inspection and

attaching accessories, etc.,

it will be shipped to maintenance shops nationwide.